And supplies complete flexibility thanks to the completely different application-specific options, their ease of integration. These palletizers have adaptable software that doesn't require reprogramming and are able to handling ... The totally computerized palletizing techniques MSK Triotech and MSK Duotech are single-pillar-palletizing methods with a swivel arm which can additionally be used for depalletizing.

They can be found in many alternative configurations and can improve your productivity in phrases of getting ready large amounts of products for shipment or storage. When you start wanting into automated palletizing, you may feel overwhelmed. That’s why we’re sharing what you need to know beforehand, so that you may be ready to reply the proper questions and discover precisely what you need. Dematic provides a portfolio of user-friendly, cost-effective, high-performance palletising and depalletising systems to handle the complexities of distribution operations. From manual ergonomic palletising & depalletising stations to completely automated robotic options, Dematic modular methods provide maximum performance, flexibility, and reliability. With Columbia’s superior Product Manager graphic-based HMI, our conventional palletizers provide limitless pattern-forming capabilities and zero time — zero software changeover automated palletizer.

Our Automated Robotic Palletizer is on the market for all types of merchandise and production speeds. With a compact footprint, the Automated Robotic Palletizer uses highly dependable FANUC robots and may accommodate GMA, CHEP and Euro pallets. A Columbia palletizer machine can deal with your particular product combine with proven modular elements that can be positioned on most all fashions to softly and efficiently stack your package sort.

FANUC has the business's most strong palletizing robotic lineup to match any payload requirement. Modular design is scalable for small, mid-size and enormous distribution facilities. This permits growing enterprise and corporations to extend throughput capability and to handle peak demands effectively. Each pallet is all the time built stable, appropriate, and store-friendly, lowering your in-store costs at shelf refilling. Modular design is scalable for mid-size and enormous distribution facilities.

Multi-axis automation products including H-Bots, T-Bots, Gantries, and Cartesian Robots. Alex Owen-Hill is a contract writer and public speaker who blogs about a wide variety of subjects, together with science, presentation skills at CreateClarifyArticulate.com, storytelling and robotics. He completed a PhD in Telerobotics from Universidad Politecnica de Madrid as a half of the PURESAFE project, in collaboration with CERN. As a recovering academic, he maintains a firm foot within the robotics world by running a blog about industrial robotics.

What To Learn About Automated Palletizing

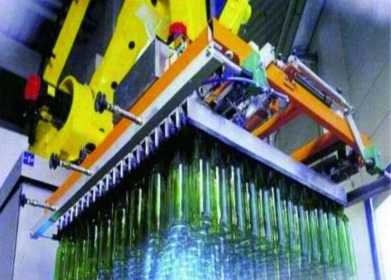

Automated palletizing options were developed to reduce worker injury and velocity up production processes, ensuing within the row-formed machine, which positioned pallet merchandise in neat rows. Today, fashionable palletizing machines function superior technologies like robotics and computers, and so they can manage objects that are difficult to palletize by hand, similar to bottles. Columbia's conventional excessive stage palletizer machines set the business commonplace. Each of these palletizing machines could be upgraded as your business needs change, while adaptable interfaces allow for easy integration together with your production equipment. Massman Automation offers a small footprint, low-cost gantry palletizing solution, a high-entry palletizing answer, and robotic palletizing solutions able to dealing with a number of conveyor traces.

- This system is capable to automatically palletized the models for PVC, PE and PP pipes with or with out sockets.

- Modular design is scalable for mid-size and enormous distribution facilities.

- A robotic palletizer includes a computer-operated, electro-mechanical machine that may perform varied tasks on its own.

- You can safe top-of-the-line palletizing equipment that sets the standard for innovation and user-friendly operation at Massman.

- Robotic palletizing methods are reliable, flexible and improve productiveness with only a small gear footprint and due to this fact have turn into a extra best resolution for a wider vary of packing scenarios.

Employment Columbia is all the time seeking talented people to affix our world-class employees.Trade shows Columbia manufactures inline, excessive level, floor stage palletizers, LTS items and systems integration. The robotic palletizer is able to choosing a quantity of instances with vacuum or mechanical end-of-arm tooling and constructing the desired pallet pattern. A high-level infeed layer palletiser, with its high running speed it is well fitted to end-of-line and centralized multi-load purposes. High performance layer palletiser that can deal with as much as 140 cases/minute. In addition, palletizing robots could be programmed to handle multiple infeeds of various SKUs on the identical line. Vision methods can be utilized to ship information to the robot so it could choose and place completely different SKUs on totally different pallets.

In comparison with typical layer palletizers, they require less space, depart much less room for error and are total higher equipped to handle a quantity of duties. A robotic palletizer can deal with one or more items at a time according to pallet configuration, and forms a quantity of layers on a pallet after picking the merchandise off of a conveyor. Robotic palletizing solutions can simply accommodate totally different pallet patterns and product sorts. We provide complete automated palletizing options, encompassing the layer and robot palletizer hardware, the palletization software program, and the system integration. Designed to palletize and transport almost any product, our options assist a wide range of industries, from tissue and paper processing to chemical and meals distribution.

The working course of, fully computerized, is managed by a P.L.C. WORKING CYCLE DESCRIPTION The merchandise in arrival ... Decase/Depalletize - Courtesy of StrongPoint Automation - PalletTool supports fixed location depalletizing if half places differ or part size and type are randomized a vision system might be required. Recognition, sorting and height detection can all be achieved using clever imaginative and prescient systemsor a 3D space sensor for depalletizing operations. Using a 3D space sensor allows depalletizing each homogeneous and heterogeneous unit masses. Tray based solution lets you deal with a wide range of merchandise and offers you flexibility for future modifications in product packaging.

Reduces warehouse labor prices and selecting failures compared to manual solutions. The resolution is designed to grow as your corporation grows, with semi-automated and totally automated modules. ACPaQ is universally relevant for totally automated order choosing of blended case pallets. The interlayers or pallets choosing and placing features can be either carried out by the choosing device or by peripheral system.

Layer Palletizermwpy

Dematic is a number one provider of built-in automated expertise, software program and companies to optimise the provision chain. Using a novel, versatile belt based mostly “rack and pinion” design and structural aluminum MacFRAME parts, our Robotic Transport Units can handle all kinds of lengths and payloads. Simple and economical, screw pushed actuators are highly modifiable for various applications and excellent for lighter masses and high accuracy positioning.

They employ specialised palletizing robots designed to carry complete layers of product in one movement. Conventional automatic palletizing machines have been the dominant sort of automated palletizer for years. You can secure top-of-the-line palletizing tools that sets the usual for innovation and user-friendly operation at Massman. We’ve spent over four many years creating normal and custom palletizing options that meet our customers’ needs.

Thanks to its self-supporting structure with wheels, the tools may be easily moved at the manufacturing facility to service any line. • - Possibility to course of pipe bundles or pipe packages fixed by saddles ; • - Quick and ... A range of lightweight gear for conveying goods productively through a manufacturing plant. We present skilled recommendation and assist throughout project implementation and past, guaranteeing our customers are all the time able to get probably the most out our pallet automation methods.

That method you'll find a way to clearly see how you will experience a return in your funding and how many months it will take to steadiness out your budget. Dematic is optimising your provide chain with applied sciences that are reworking your industry. Please describe the container that must be palletized and list your speed necessities. Our certified gross sales engineers and project managers are dedicated to finding the right solutions to match our customers’ wants, nonetheless advanced they could be.

The GR-X automated palletizer system is designed to organize full-height pallets measuring 44”W x 56”L x 110” tall of empty plastic containers or aluminum cans. Unit is configured to deal with the range of container/can sizes and pace of your line. Palletizer operator to be responsible for loading empty pallet, initiating automatic sequence, fastening of pallet banding , putting slip-sheets between layers, and elimination of full pallet. Options to routinely load/remove pallet and routinely place slip-sheet layers are available. Industrial robot palletizers tend to be very massive and take a lengthy time to deploy.

Linear actuators offer horizontal and vertical motion with journey as much as 500 ft, speeds as much as 600 in/sec., and might accurately deal with loads up to 10,000 lbs. Builds superior quality packaging machines including bottle Unscramblers, Cappers, Orienters, Retorquers, Lidders, Scoop Feeders, Pluggers and more. Pallet packing robotic, automatic mobile, which works with the assistance of the operator to present it to the pallet to be packed.