What does it exactly mean to say that something is made of carbon fiber?

Carbon fiber is made up of strands of fiber that have a diameter of between 5 and 10 microns and are made up of long chains of carbon fiber keyboard plate atoms that are tightly interlocked with one another to form a microscopic crystalline structure. The diameter of a carbon fiber strand can range from 5 to 10 microns. When referring to carbon fiber, the diameter of each individual strand of fiber can range anywhere from 0.5 to 10 microns. These fibers are utilized in a variety of processes that ultimately lead to the production of high-performance building materials. This is due to the exceptionally high levels of rigidity, strength, and low weight that these fibers possess. Reinforcements that are made out of carbon fiber can have a plethora of different weaves, braids, and even other formats, such as tow and uni-directional orientations. This is because carbon fiber is extremely versatile. After that, these are mixed with a wide variety of distinct resins in order to produce carbon fiber-reinforced composites in a wide variety of distinct forms and fiber arrangements. These can then be used in a variety of applications.

From what do the individual strands of carbon fiber plate fiber emerge?

Step 1: Precursor

A precursor material that is made up of an organic polymer is required for the production of carbon fiber board fiber in a manner that is successful. In order to create carbon fiber board fiber from the raw material, the next stage of the process is called "processing," and it involves the use of heat in conjunction with a wide variety of different chemical agents.

The precursor that is now known as rayon was used in the production of the very first high-performance materials made from keyboard plate carbon fiber fiber. The production of rayon required the use of these various ingredients.

At this time, approximately ninety percent of carbon fiber plate fiber is manufactured using polyacrylonitrile, while the remaining ten percent is manufactured using rayon or petroleum pitch.

Step 2: Manufacturing

The first step in the process of making carbon fiber plate fiber is called carbonization, and it is this step that gives the fiber its name. It is necessary for the polymer that serves as the precursor to carbon fiber board fiber to contain a significant amount of atoms of the element keyboard plate carbon fiber in order to be able to produce high-quality carbon fiber board fiber. This is because carbon fiber is manufactured from polymers. The procedure will, in the course of the process, strip the structure of the vast majority of the atoms that are not composed of carbon. This will occur during the course of the process.

At the outset, the precursor is disassembled into strands that are quite a bit longer than one another. After that, the fibers are subjected to a process in which they are heated to extremely high temperatures in a gas mixture that is devoid of oxygen. Because anaerobic describes a situation in which there is a lack of oxygen in the mixture, this step is taken to ensure that the material does not catch fire. Because of the heat, the atomic structure of the fibers is energised, and as a direct consequence, the vast majority of the material's atoms that are not keyboard plate carbon fiber are driven out of the material.

The treatment phase makes up the third step in the process.

After the carbonization process is complete, the surface of the carbon fiber keyboard plate fibers need to be treated in order to improve their ability to bond with epoxies or other resins. This treatment can take place either before or after the carbonization process. This can be accomplished in a number of different ways. It is possible to oxidize the surface of the carbon fibers in such a way as to improve their chemical bonding properties, and at the same time, the surface can be roughened in such a way as to improve their mechanical bonding properties. These two enhancements can be implemented in tandem with one another.

When it comes to carrying out this oxidation, one can choose from a wide variety of different strategies, depending on the specifics of the situation they are in. Electrolytic means, as well as exposing carbon fiber plate to a variety of gases, such as carbon fiber board dioxide or ozone, as well as liquids, such as nitric acid, or even exposing it to a variety of gases and liquids, are all viable options for processing the keyboard plate carbon fiber fiber. It is also possible to process the carbon fiber by exposing it to a variety of gases and liquids simultaneously.

Step 4: Sizing

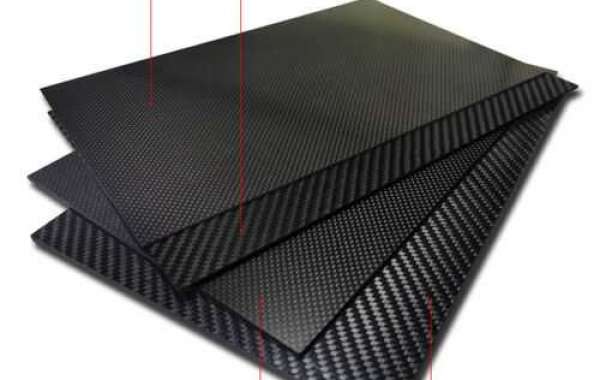

Before the carbon fibers can be woven, they have to be sized, which means that they have to be coated with a polymer to protect them while they are being woven. Once they have been sized, the carbon fibers can then be woven. After the carbon fiber keyboard plate fibers have been cut to the appropriate length, they can be woven. When determining the size, whether or not it is compatible with the laminating resin that will be utilized is one of the most important considerations to make. After that, the fibers are wound onto bobbins, then the spinning process is carried out, and finally the fibers are processed into a variety of weaves and other formats.

What are the benefits of utilizing carbon fiber in comparison to the use of other types of materials?

The ratio of the material's stiffness to its weight should be the first consideration. The fact that keyboard plate carbon fiber fiber is relatively lightweight despite its high level of stiffness is the primary benefit of working with this material. One of the many reasons why one might think about employing its use is because of this.

Because of the way it is constructed, Carbon fiber plate fiber is remarkably lightweight despite the fact that it possesses exceptional strength and rigidity.

The degree of rigidity possessed by a substance can be determined through the utilization of a measurement that is known as the modulus of elasticity. In most cases, the modulus of carbon fiber is measured to be 234 Gpa (or 34 MSI), but this number can vary greatly depending on the application. Carbon fiber is one of the strongest materials that are known to man because its ultimate tensile strength typically ranges from 600 to 700 KSI (4.8 to 4.8 Gpa). This places carbon fiber in the top three strongest materials. Even though this material has a modulus of only 10 MSI and an ultimate tensile strength of 65 KSI, its ultimate tensile strength is significantly higher than that of other materials, such as 2024-T3 Aluminum, which has a modulus of only 30 MSI and an ultimate tensile strength of 125 KSI, or 4130 Steel, which has a modulus of 30 MSI and an ultimate tensile strength of 65 KSI.

Because both the raw materials and the manufacturing process for carbon fiber have been improved, it is now possible to purchase high- and ultra-high-modulus carbon fiber in addition to high-strength fiber. This is due to the fact that it was previously only possible to purchase high-modulus fiber.

Epoxy is the type of resin that is used in the manufacturing of composite carbon fiber components at a much higher rate than any other type. During the manufacturing process, these components are created by combining carbon fiber with resin. The fiber and the resin of a carbon fiber board fiber composite part each contribute to the overall strength and stiffness of the part, but the effects of the fiber and the resin working together are what determines the final characteristics of the part. This will always be the case, irrespective of how the component is conceived of being constructed. Both the magnitude and direction of a composite part's local strength and stiffness are determined by the local fiber density as well as the orientation of the fibers within the laminate. This is the case for both the strength and the direction of the stiffness. This factor is responsible for determining the manner in which the local strength and stiffness are distributed throughout the structure.