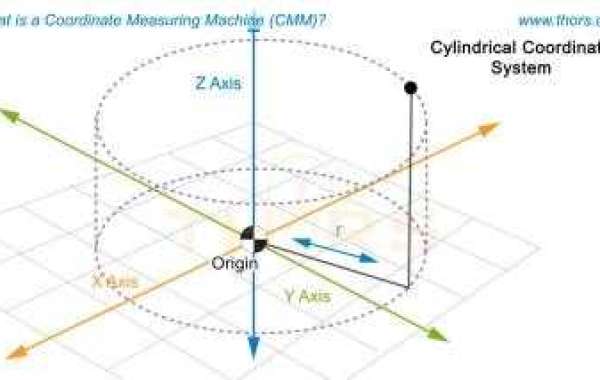

A Coordinate Measuring Machine, or CMM for short, is a specialized type of measuring device that can be used to measure the dimensions and geometry of physical objects with a high level of accuracy. It is a mechanical system that uses a probe to sense the three-dimensional coordinates of the object being measured. These coordinates are then used to create a digital representation of the shape of the object based on the information that was gathered from the probe. Common components of a coordinate measuring cmm inspection services (CMM) include a measuring probe, a measuring table, and a computer system that is used to control the movements of the probe and analyze the data that is collected. The probe is held in place by a movable arm that has the ability to move in all three dimensions along the axes of X, Y, and Z. The object being measured can rest securely and evenly distributed across the surface of the measuring table while it is being evaluated. The coordinates of the points that the probe touches while it is being moved along a predetermined path are recorded by the CMM as it performs the measurement of the object. After that, these points are used to create a three-dimensional map of the surface of the object, which can then be used to conduct an analysis of the object's dimensions, shape, and position.

In manufacturing and quality control settings, CMMs are frequently used to ensure that parts are manufactured according to the appropriate specifications and tolerances. The primary purpose of a coordinate measuring cmm inspection services (CMM) is to precisely measure the dimensions of an object, such as the object's position, size, and shape. This is achieved by moving the probe along the surface of the object and recording the coordinates of the points it touches as it moves along the surface of the object. After gathering these coordinates, a digital representation of the object's shape can be constructed using them. CMMs are capable of being programmed to measure particular aspects of an object, such as the angles, curves, or holes in it. In addition, you can use them to perform geometric comparisons between a real-world object and its original design or specifications by using them. In addition, CMMs can be used to measure the dimensions of complex shapes, which can be difficult to measure using traditional measurement tools. This is possible because CMMs are three-dimensional measuring machines.

CMMs are put to use in a wide variety of manufacturing and quality control applications to ensure that finished products are produced according to the required specifications and tolerances. They are also put to use in research and development applications, where they are used to investigate the structure and characteristics of new products and materials.

Additionally, it may be outfitted with fixtures and clamps that are designed to keep the object in place while it is being measured. It's possible that the measuring table can be moved around so that measurements can be taken in a variety of places on the thing being measured. Control System: The control system is a computer system that analyzes the data collected and controls the movements of the probe. It also controls the movements of the probe. The control system contains software that enables the user to program the CMM for specific measurements and analyses. Additionally, the control system may contain data storage and management tools for the purpose of arranging and analyzing measurement data. These four components must be meticulously calibrated and maintained to ensure accurate and reliable results. Working together, they provide precise measurements of the object that is being measured.