universal grinder grinding stainless steel tank part time stamping molding, and the grinding tank surface polishing treatment appropriate to use, easy to clean after the universal grinder; inferior universal mill crushing tank made of iron and wall electroplating method for surface treatment, though looks bright as a mirror, but generally use 2-3 times after plating layer will wear, exposing the black iron base, prone to corrosion or damp wet cleaned without timely dry, used for next time.

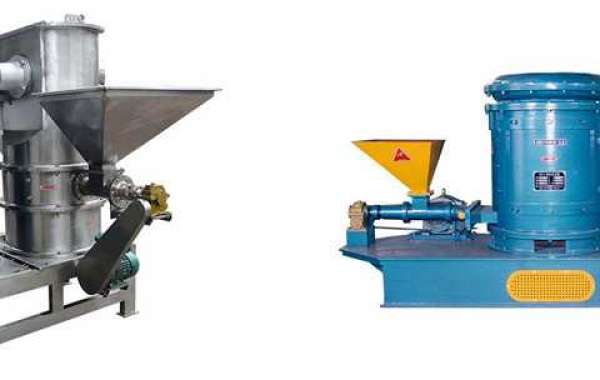

Low-speed pulverizers

A ball mill pulverizer is the one that has a horizontal rotating cylinder. It consists of a charge of tumbling. It might also have steel balls, rods or pebbles. When it comes to tube mill, it is revolving cylinder that is used for the pulverization of the ore, rock and many other hard materials. The material that needs to be pulverized is mixed with water, and it is fed into the chamber, and it comes out as slurry. In both ball and tube mills, the loners protect the cylindrical structure. But the balls undergo wear and tear and hence they need to be replaced when it is required.

Medium speed

This is the kind of mill that has two kinds of rings. Both the rings are separate from each other, and they are separated by large ball bearings. There are springs and adjuster assemblies in the mill. The material that has to be pulverized is loaded in the center or on the side. The air flow in the pulverizer carries out the pulverized material. The size of the pulverized material totally depends on the classifier separator. If the coal or any other material for that matter is light enough to be picked by the air, it goes to the classifier.

High speed

An attrition mill is a machine that is used to reduce the size of the solid particles. In ten hours, milling, 40 and 25 m2/g were obtained for alumina and barite. These are generally used in heavy industries that subjects different kinds of materials to size reduction. There will be a considerable difference after subjecting different materials to this particular pulverizer. The characteristics of the attrition pulverizer are very the same as the radial flow turbine mixer. The difference depends on the size and density of the particular material.

Pulverizer grinder bearing parts quality

high quality motor universal grinder generally adopts imported bearing assembly, to ensure that the motor in high speed rotation process 25000 RPM in lubrication condition, not overheating; the inferior universal grinder market very cheap inferior bearing assembly, thereby reducing the cost of the machine, do sacrifice life.

The safety coefficient of universal grinder circuit

high quality universal grinder motor with GB enamelled wire winding motor rotor winding and custom parts, advantages of copper wire is low resistance, high strength, heat resistance, and long service life, work is not easy to generate heat; the inferior universal grinder used in motor winding aluminum core wire winding, high resistance, so the work fast heating, easy motor overheating damage.

Pulverizer grinding machine continuous processing capacity

universal grinder grinding can be continuously above 10kg Chinese herbal medicine or food materials and will not affect the service life of the product, it is often the only inferior universal grinder grinding 1-2kg material body feels very hot, this is if you don’t stop working will cause the motor burned, thus losing warranty.

If you are interested in the pulverizer machine price and details, just contact me

Address

No.2388 Shengzhou Avenue, Shanhu street, Shengzhou City, Zhejiang Province.

Tel

0086 575 8310 6186

Web:

https://www.sunwellpulverizer.com/product/shredder-series/